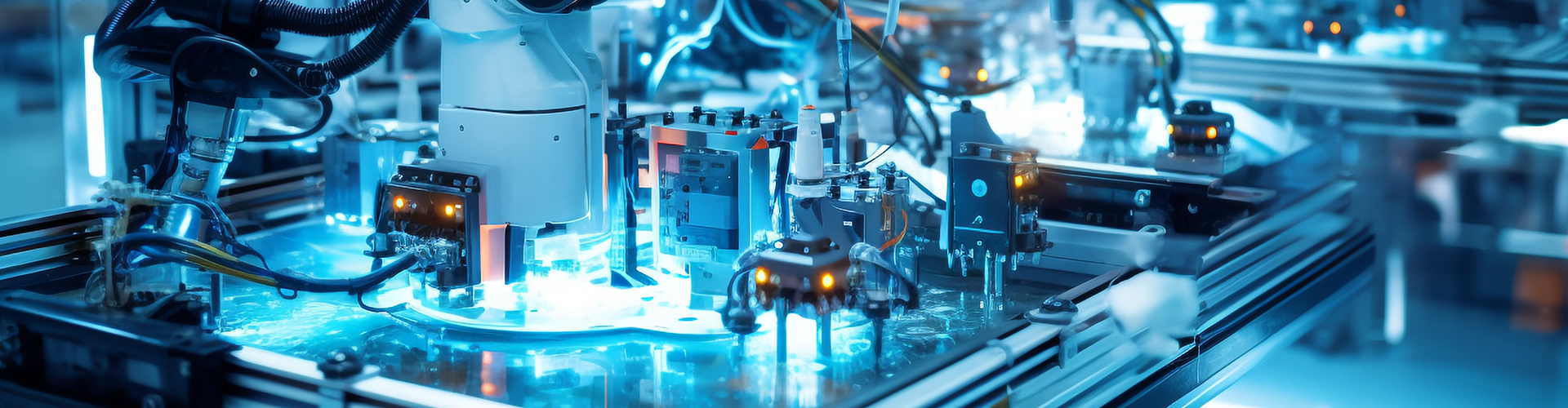

International Advanced Intelligent Equipment for Industry 4.0

Establishing a world-leading smart manufacturing 'lights-out factory' for 24/7 intelligent automated production

Smart Vertical Logistics System

Smart Vertical Logistics System

AI-powered sorting system automatically delivers materials to slitting/cross-cutting & packaging units with precision timing and dosing, increasing throughput efficiency ≥20%

-

One-Stop Intelligent Distribution System

We interconnect production, warehouse and other systems, enabling real-time one-stop intelligent distribution of materials according to system instructions, enhancing production efficiency.

-

No crane forklift operation

We use automatic equipment, such as aisle stackers, to achieve automatic access and handling of silicon steel coils, ensuring the safety of our staff and materials.

-

Stereo smart warehousing system

We adopt a high-level stereo design to achieve vertical storage of silicon steel coils, significantly improving warehouse space utilization (2-5 times more than ordinary flat warehouses). Additionally, maintaining a constant temperature and humidity environment not only extends the storage time of steel coils but also ensures the stability of material quality.

-

Full-link traceability

By implementing an automated data collection and recording system, we ensure precise inventory management and optimize warehouse operations, providing better insights into the supply chain and enabling more accurate decision-making.

USL Silicon Steel - Automated High Bay Storage and Logistic Facility for Master Coils

-

Warehouse Capacity

5,000 Tons

-

Warehouse Storage Unit

200

-

Load of Each Stand

25tons

-

Throughput Speed

40 coils/hour

USL Silicon Steel - Automated High Bay Storage and Logistic Facility for Slit Coils

-

Warehouse Capacity

6,000 tons

-

Warehouse Storage Unit

1,200

-

Load of Each Stand

5 tons

-

Throughput Speed

40 coils/hour

Slitting Lines Equipped with Real-time Iron Loss and Thickness Detector

Slitting Lines Equipped with Real-time Iron Loss and Thickness Detector

A self-developed, centrally-positioned slitting line, equipped with intelligent tension roller and online thickness and iron loss measurement system, can ensure the surface quality and performance of raw materials during shearing, and accurately record the material loss after shearing.

-

Online Real-time Monitoring System

Our Online Real-time Monitoring System can detect the entire surface of silicon steel, and upload real-time date to the background database, allowing for accurate monitoring of iron loss and thickness of products. This real-time data helps to improve product quality, and ensure that products meet quality standards.

-

Automatic Dedusting System

Our automatic dedusting system is capable of quickly and effectively removing dust generated during the cutting process. This ensures the cleanliness of the silicon steel surface and enhances product performance.

-

Intelligent Tension Roller System

PTTX's patented automatic tension system accurately controls the material tension to prevent folding or collapse during coiling. This ensures the flatness and dimensional accuracy of the product.

-

Efficient Blade Change System

PTTX has upgraded the traditional horizontal straight cutting technology to spiral shearing, which significantly reduces the creation of burrs, and helps to increase the lifespan of blades, reduce production costs and maintenance frequency.

-

Uncoil Weight

22 tons

-

Uncoil Width

30-1,300mm

-

Winding Width

30-1,250mm

-

Slitting Speed

200m/min

-

Width Precision

-0.2mm-0mm

-

Burr Height

≤0.015mm

-

Edge Camber

<0.1mm/2,000mm

-

Winding Deviation

±0.1mm

Full Sequence Cutting to Length Lines with Automated Inline Lamination System

Full Sequence Cutting to Length Lines with Automated Inline Lamination System

By integrating multiple automation and intelligent technologies, the system can realize fully sequenced production processes such as automatic fetching, horizontal shearing, stacking, and material alignment of silicon steel coils, greatly improving production efficiency and product accuracy.

-

Intelligent Unmanned Production Line

In this unit, we achieve full-sequence automated shearing, material handling and stacking. It also eliminates the need for lifting machinery throughout the entire sequence, minimizing manual contact to ensure product quality. Our production line supports uninterrupted 24-hour production.

-

Intelligent Automatic Coil Handling System

Cross-arm equipment realizes automatic fetching and changing of silicon steel in the warehouse through advanced system control, greatly improving material changing efficiency; With high-precision positioning and sensing technology, it ensures accurate entry of coils into the horizontal shearing equipment, effectively eliminating product quality problems caused by errors.

-

Full Sequence Production

The full sequence automated cutting to length lines with inline laminations unit can achieve synchronized and gradual production of the same silicon steel coil, eliminating the common industry issue of thickness variation between transformer core columns, ensuring consistency in thickness, iron loss, magnetic.

-

Shearing Thickness

0.18-0.3mm

-

Burr Height

<0.015mm

-

Angle Precision

<0.0015°

-

Length Precision

-0.3mm-0mm

-

Machine

Full sequence cutting to length lines + Automated Inline Lamination System

Full sequence cutting to length lines + Automated Inline e-stacker

-

Shearing Width

100-1,000mm

100-850mm

-

Shearing Length

≤6,000mm

≤5,500mm

USL Silicon Steel Automatic Packaging System

USL Silicon Steel Automatic Packaging System

The fully automatic packaging line for USL silicon steel significantly improves packaging efficiency with its efficient, precise, and contactless characteristics, avoiding the impact of human factors on packaging quality.

-

Fully Automatic Packaging

Integrated with advanced automation technology and intelligent control system, 24-hour non-stop production, the fully automatic packaging improves efficiency and significantly reduces labor costs.

-

High-precision Packaging

Equipped with high-precision (2000+ sensors) sensing equipment, it ensures the uniformity of size and position for packaing materials, such as gas phase rust-proof paper, winding film, anti-collision strip, etc.

-

Contactless Packaging

Contactless operation reduces manual intervention, lowering the risk of product contamination due to human factors. It also reduces the risks associated with manual operations, preventing safety accidents from occurring.

-

Anti-Rust & Moisture-Proof Packaging Process

Using composite materials (rust-proof paper + agricultural film) and automated layered-sealing packaging with precision roller compaction to achieve optimal anti-rust and moisture-proof protection

-

Machine

Automated Packing Systems for Mother Coils

Automated Packing Systems for Slit Coils

-

Packaging Width

≥300mm

<300mm

-

Packaging Speed

About 5-7min

About 5-7min